Enter your VAT number here and click Verify:

Your details have been verified. VAT number registered to:

,

.

Your order will now be zero rated for VAT purposes. We reserve the right to verify these details after your order request has been made and reinstate VAT if required.

Your VAT details were not recognised or were invalid. Your VAT number must be matched to your Billing Country as specified above. This is currently specified as . You do not need to enter the country code part of your VAT number as this has already been selected in your billing address details above.

The VAT number checking service is currently offline. Please supply your VAT details within the comments or special instructions field below and we will apply a VAT discount after placing your order request.

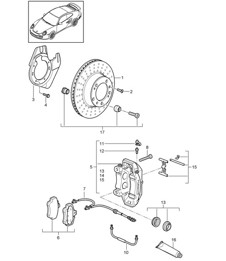

Replacement for Ceramic Disc

Porsche 911 (997) GT3 2008>> Onwards

Porsche 911 (997) GT2 / GT2 RS 2007>> Onwards

*For cars with Ceramic Disc

Original Porsche

Sold as set of 4 pads for one axle.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

99735294790

The product you are viewing cross references to these numbers

- Porsche 997 MK1 GT3 2007-09

- Porsche 997 MK1 GT2 2007-09

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Brake Disc Ø: 380mm

Brake Disc Thickness: 34 mm

Upgrade the braking performance of your performance Porsche with DesignTek Carbon Ceramic Front Brake Discs — engineered for drivers who demand exceptional stopping power, consistent performance, and long-life durability on both road and track.

Fits:

Porsche 997 MK1 TURBO 2007-09

Porsche 997 MK1 GT3 2007-09

Porsche 997 MK1 GT2 2007-09

Porsche 997 MKII GT3 2010-11

Porsche 997 MKII Turbo 2010-13

Porsche 997 MKII GT2 RS 2011-13

Crafted to be a direct OE-replacement fit, these carbon ceramic discs deliver a substantial enhancement over conventional cast iron brakes. They maintain consistent performance throughout a wide temperature range, resist fade under repeated hard use, and significantly reduce unsprung mass for improved vehicle dynamics. Whether you’re pushing your Porsche hard on track days or seeking superior braking feel and reduced dust for aggressive street performance, DesignTek Carbon Ceramic Front Brake Discs offer a premium, precision-engineered solution.

Product Features:

- Carbon ceramic construction for high heat tolerance and fade-resistant braking

- Direct OE replacement fitment for vehicles originally equipped with carbon ceramic systems

- Lightweight design reduces unsprung and rotating mass for quicker response

- Exceptional thermal stability and wear resistance

- Designed for use with OE and compatible aftermarket calipers

- Pairs perfectly with DesignTek CCB-compatible brake pads (recommended)

- Ideal for high-performance road use and track performance driving

Important Fitment & Usage Notes:

- Carbon ceramic discs must be used with CCB-compatible brake pads — not standard iron-disc pads

- Compatible with OE and selected aftermarket calipers that are designed for carbon ceramic use

- Not suitable for use with pads or calipers that aren’t expressly rated for carbon ceramic applications

- Before ordering, please confirm caliper compatibility and pad selection to ensure optimal performance and safety.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

36040097TCF

The product you are viewing cross references to these numbers

- Porsche 997 MK1 TURBO 2007-09

- Porsche 997 MK1 GT3 2007-09

- Porsche 997 MK1 GT2 2007-09

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII Turbo 2010-13

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Brake Disc Ø: 380mm

Brake Disc Thickness: 30mm

Upgrade the braking performance of your performance Porsche with DesignTek Carbon Ceramic Rear Brake Discs — engineered for drivers who demand exceptional stopping power, consistent performance, and long-life durability on both road and track.

Fits:

Porsche 997 MK1 TURBO 2007-09

Porsche 997 MK1 GT3 2007-09

Porsche 997 MK1 GT2 2007-09

Porsche 997 MKII GT3 2010-11

Porsche 997 MKII Turbo 2010-13

Porsche 997 MKII GT2 RS 2011-13

Crafted to be a direct OE-replacement fit, these carbon ceramic discs deliver a substantial enhancement over conventional cast iron brakes. They maintain consistent performance throughout a wide temperature range, resist fade under repeated hard use, and significantly reduce unsprung mass for improved vehicle dynamics. Whether you’re pushing your Porsche hard on track days or seeking superior braking feel and reduced dust for aggressive street performance, DesignTek Carbon Ceramic Rear Brake Discs offer a premium, precision-engineered solution.

Product Features:

- Carbon ceramic construction for high heat tolerance and fade-resistant braking

- Direct OE replacement fitment for vehicles originally equipped with carbon ceramic systems

- Lightweight design reduces unsprung and rotating mass for quicker response

- Exceptional thermal stability and wear resistance

- Designed for use with OE and compatible aftermarket calipers

- Pairs perfectly with DesignTek CCB-compatible brake pads (recommended)

- Ideal for high-performance road use and track performance driving

Important Fitment & Usage Notes:

- Carbon ceramic discs must be used with CCB-compatible brake pads — not standard iron-disc pads

- Compatible with OE and selected aftermarket calipers that are designed for carbon ceramic use

- Not suitable for use with pads or calipers that aren’t expressly rated for carbon ceramic applications

- Before ordering, please confirm caliper compatibility and pad selection to ensure optimal performance and safety.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

36040097TCR

The product you are viewing cross references to these numbers

- Porsche 997 MK1 TURBO 2007-09

- Porsche 997 MK1 GT3 2007-09

- Porsche 997 MK1 GT2 2007-09

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII Turbo 2010-13

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

DesignTek Carbon Ceramic Front Brake Pads are engineered specifically for use with carbon ceramic brake discs, delivering consistent, fade-resistant braking performance for both high-performance road driving and track use.

Unlike conventional brake pads designed for iron discs, these pads use a carbon-ceramic-compatible friction compound that operates effectively across a wide temperature range without damaging the disc surface. The result is strong, progressive braking feel, excellent modulation, and stable performance under repeated heavy braking.

Ideal for drivers seeking a refined street braking experience with the durability and performance required for spirited or track-focused driving, DesignTek brake pads offer a reliable OE-replacement solution for Porsche carbon ceramic braking systems.

Fits:

Porsche Boxster 987 2.7L 2005 -08/08

Porsche Boxster 987 S 3.2/3.4L 2005-08/08

Porsche Boxster 987 MKII 2.9L 2009-2012

Porsche Boxster S 987 MKII 3.4L 2009-2012

Porsche 996 GT2 2001-05

Porsche 996 GT3 MKI 1999-02

Porsche 996 GT3 MKII 2003>>

Porsche 997 MK1 Carrera 2 3.6L 2005-08

Porsche 997 MK1 GT3 2007-09

Porsche 997 MK1 GT2 2007-09

Porsche 997 MKII GT3 2010-11

Porsche 997 MKII GT2 RS 2011-13

Porsche Cayman 2.7L 987C 2006-08

Porsche Cayman S 3.4L 987C 2005-08

Porsche Cayman 2.9L 987C MKII 2009-12

Porsche Cayman S / R 3.4L 987C MKII 2009-12

Porsche Carrera GT

Key Features:

- Specifically formulated for carbon ceramic brake discs

- Suitable for street and track use

- Excellent fade resistance at elevated temperatures

- Consistent friction characteristics across the full operating range

- Progressive pedal feel and strong initial bite

- Low dust output compared to conventional iron-disc pads

- Designed for use with OE and compatible aftermarket calipers

- Both Street and Race Pads are ECE R90 E11 Certified, ensuring no compliance issues

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

36040099059

The product you are viewing cross references to these numbers

- Porsche Boxster 987 2.7L 2005-08/08

- Porsche Boxster 987 S 3.2/3.4L 2005-08/08

- Porsche Boxster 987 MKII 2.9L 2009-12

- Porsche Boxster S 987 MKII 3.4L 2009-12

- Porsche 996 GT2 2001-05

- Porsche 996 GT3 MKI 1999-02

- Porsche 996 GT3 MKII 2003>>

- Porsche 997 MK1 Carrera 2 3.6L 2005-08

- Porsche 997 MK1 GT3 2007-09

- Porsche 997 MK1 GT2 2007-09

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII GT2 RS 2011-13

- Porsche Cayman 2.7L 987C 2006-08

- Porsche Cayman S 3.4L 987C 2005-08

- Porsche Cayman 2.9L 987C MKII 2009-12

- Porsche Cayman S / R 3.4L 987C MKII 2009-12

- Porsche Carrera GT 2003-06

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

DesignTek Carbon Ceramic Rear Brake Pads are engineered specifically for use with carbon ceramic brake discs, delivering consistent, fade-resistant braking performance for both high-performance road driving and track use.

Unlike conventional brake pads designed for iron discs, these pads use a carbon-ceramic-compatible friction compound that operates effectively across a wide temperature range without damaging the disc surface. The result is strong, progressive braking feel, excellent modulation, and stable performance under repeated heavy braking.

Ideal for drivers seeking a refined street braking experience with the durability and performance required for spirited or track-focused driving, DesignTek brake pads offer a reliable OE-replacement solution for Porsche carbon ceramic braking systems.

Fits:

Porsche 997 MK1 Carrera 2 3.6L 2005-08

Porsche 997 MK1 Carrera 2S 3.8L 2005-08

Porsche 997 MK1 Carrera 4 3.6L 2005-08

Porsche 997 MK1 Carrera 4S 3.8L 2005-08

Porsche 997 MK1 TURBO 2007-09

Porsche 997 MK1 GT3 2007-09

Porsche 997 MK1 GT2 2007-09

Porsche 997 MKII Carrera C2 3.6L 2009-12

Porsche 997 MKII Carrera C4 3.6L 2009-12

Porsche 997 MKII Carrera C2S 3.8L 2009-12

Porsche 997 MKII Carrera C4S 3.8L 2009-12

Porsche 997 MKII GT3 2010-11

Porsche 997 MKII Turbo 2010-13

Porsche 997 MKII GT2 RS 2011-13

Key Features:

- Specifically formulated for carbon ceramic brake discs

- Suitable for street and track use

- Excellent fade resistance at elevated temperatures

- Consistent friction characteristics across the full operating range

- Progressive pedal feel and strong initial bite

- Low dust output compared to conventional iron-disc pads

- Designed for use with OE and compatible aftermarket calipers

- Both Street and Race Pads are ECE R90 E11 Certified, ensuring no compliance issues

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

36040099079

The product you are viewing cross references to these numbers

- Porsche 997 MK1 Carrera 2 3.6L 2005-08

- Porsche 997 MK1 Carrera 2S 3.8L 2005-08

- Porsche 997 MK1 Carrera 4 3.6L 2005-08

- Porsche 997 MK1 Carrera 4S 3.8L 2005-08

- Porsche 997 MK1 TURBO 2007-09

- Porsche 997 MK1 GT3 2007-09

- Porsche 997 MK1 GT2 2007-09

- Porsche 997 MKII Carrera C2 3.6L 2009-12

- Porsche 997 MKII Carrera C4 3.6L 2009-12

- Porsche 997 MKII Carrera C2S 3.8L 2009-12

- Porsche 997 MKII Carrera C4S 3.8L 2009-12

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII Turbo 2010-13

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

NEWLY DEVELOPED BRAKE PADS FOR CERAMIC DISCS.

This Product Fits:

Porsche 997 all models ceramic brakes 2005-12 (Rear)

Pad thickness: 19mm

PAGID Racing RSC compounds are developed to comply with the latest requirements in ceramic composite brake disc technology and meet or surpass all current ecological standards of the automotive industry.

RSC 1 is a low metallic resin bonded material containing steel and aramid fibers. This material features good all-round characteristics and is suitable for all types of usage.

• MEDIUM FRICTION COEFFICIENT

• GOOD ALLROUND PERFORMANCE CHARACTERISTICS

• DISC FRIENDLY

APPLICATION RANGE: Race and track day compound for all known types of ceramic brake discs.

RSC 3 is a low metallic resin bonded material containing steel fibers. This material is specifically developed for above mentioned applications.

• HIGH FRICTION COEFFICIENT

• EXCELLENT FADE RESISTANCE

• LONG PAD LIFE

APPLICATION RANGE: Special race compound for ceramic discs with low content of fibers in the friction surface for sprint and endurance circuit racing.

Information about Friction vs Temperature

Information about Racing Compound Characteristics

Information about Brake Pad Size

Sold as set of 4 pads for one axle.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

E8006RSC

The product you are viewing cross references to these numbers

- Porsche 997 MK1 Carrera 2 3.6L 2005-08

- Porsche 997 MK1 Carrera 2S 3.8L 2005-08

- Porsche 997 MK1 Carrera 4 3.6L 2005-08

- Porsche 997 MK1 Carrera 4S 3.8L 2005-08

- Porsche 997 MK1 TURBO 2007-09

- Porsche 997 MK1 GT3 2007-09

- Porsche 997 MK1 GT2 2007-09

- Porsche 997 MKII Carrera C2 3.6L 2009-12

- Porsche 997 MKII Carrera C4 3.6L 2009-12

- Porsche 997 MKII Carrera C2S 3.8L 2009-12

- Porsche 997 MKII Carrera C4S 3.8L 2009-12

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII Turbo 2010-13

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Made of HTCIC (High-Tech-Cast Iron-Carbon)

Characteristics "Drilled":

Drilled brake discs lead off the emerging braking heat faster than undrilled discs because of the high ventilation at the bigger radiation surface.

The original brake discs are replaced with the "o-brake.com" HTCIC high performance brake discs by easy "plug and play" mounting, which we are happy to offer and is available at any specialist workshop. Compared to the conventional gray cast iron brake discs, the highly durable HTCIC (High Tech Cast Iron Carbon) material is revolutionary, even ceramic brake discs are outperformed (responding qualities are present in both cold and hot condition). Further essential advantages are: Extremely high fading level, highest thermal stability possible, precise modulation as well as an affordable price. All our high performance brake parts are compatible with your car's safety features such as ABS, ESP, PSM, etc.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

2112121

The product you are viewing cross references to these numbers

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Made of HTCIC (High-Tech-Cast Iron-Carbon)

Characteristics "WAVE ":

Lowest weight and maximum deceleration values because of biggest radiation surface and also optimum brake pad cleaning milling (ursprünglich: vent) make this disc a vantage for motorsport use with varying conditions.

Delivery period: approx. 20 working days

The original brake discs are replaced with the "o-brake.com" HTCIC high performance brake discs by easy "plug and play" mounting, which we are happy to offer and is available at any specialist workshop. Compared to the conventional gray cast iron brake discs, the highly durable HTCIC (High Tech Cast Iron Carbon) material is revolutionary, even ceramic brake discs are outperformed (responding qualities are present in both cold and hot condition). Further essential advantages are: Extremely high fading level, highest thermal stability possible, precise modulation as well as an affordable price. All our high performance brake parts are compatible with your car's safety features such as ABS, ESP, PSM, etc.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

2112123

The product you are viewing cross references to these numbers

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Made of HTCIC (High-Tech-Cast Iron-Carbon)

Characteristics "WET":

Profiled brake discs disperse the water film from the brake disc surface within fractions of a second and provide a very short response time also in case of pouring rain.

Delivery period: approx. 20 working days

The original brake discs are replaced with the "o-brake" HTCIC high performance brake discs by easy "plug and play" mounting, which we are happy to offer and is available at any specialist workshop. Compared to the conventional gray cast iron brake discs, the highly durable HTCIC (High Tech Cast Iron Carbon) material is revolutionary, even ceramic brake discs are outperformed (responding qualities are present in both cold and hot condition). Further essential advantages are: Extremely high fading level, highest thermal stability possible, precise modulation as well as an affordable price. All our high performance brake parts are compatible with your car's safety features such as ABS, ESP, PSM, etc.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

2112122

The product you are viewing cross references to these numbers

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Replacement for cars WITH or WITHOUT Porsche Ceramic Brake (PCCB)

Internally Vented, Perforated, Coated

Outer diameter: 380 mm

Brake Disc Thickness: 34 mm

Bolt Hole Circle Ø: 130 mm

Centering Diameter: 103 mm

Total Height: 67.5mm

Replaces OEM - 99735140991 / 99735141091

PCCB - 99735103196 / 99735103296

For Track Use Only

Porsche 997.2 GT3 - 2010 to 2012 - FRONT

Porsche 997.2 GT3 RS - 2010 to 2012 - FRONT

Porsche 997.2 GT2 RS - 2011 to 2012 - FRONT

The Formula:R product line is the result of collaboration with the Zimmermann-sponsored racing team. Formula:R composite brake discs sometimes replace very expensive carbon-ceramic brake systems and are intended exclusively for use on the racetrack.

The composite technology with a light metal pot results in a significant weight reduction. This weight reduction leads to a clearly improved driving performance, since the brake discs are part of the unsprung mass. The ratio of unsprung to sprung mass is thereby increased in favor of the sprung mass. The traction and thus the control over the vehicle are noticeably improved.

Your advantages:

• Proven in racing

• Specially coated light metal pot and high-carbon cast friction ring with optimal thermal conductivity

• Highest performance of the disc even when it is temporarily hot

• Optimal ventilation and maximum stability thanks to sloping ribs in the ventilation channel

• Partly as a replacement for carbon-ceramic brake discs

• Free radial expansion through social connection of pot and friction ring

• Brake fading is avoided

• Sporty look with Z-grooves

• Developed exclusively for the race track

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

9973514

The product you are viewing cross references to these numbers

- Porsche 997 MKII GT3 2010-11

- Porsche 997 MKII GT2 RS 2011-13

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Replacement for Ceramic Discs - High-Quality Alternatives for Carbon-Ceramic Brake Systems

Replacement brake discs for ceramic systems are designed to restore braking performance on vehicles originally equipped with carbon-ceramic brake discs. These replacement options provide a practical solution when ceramic discs become worn, damaged, or prohibitively expensive to replace, while maintaining strong braking performance, predictable pedal feel, and system compatibility.

Available from Design911, replacement solutions for ceramic discs are commonly chosen by owners seeking a cost-effective, serviceable alternative that allows continued safe road or performance use without the extreme replacement costs associated with carbon-ceramic components.

What Do Replacement Discs for Ceramic Systems Do?

Replacement discs for ceramic systems work with compatible pads and calipers to safely manage braking loads.

Core Functions:

- Restore braking performance when ceramic discs are worn or damaged.

- Provide a stable friction surface for compatible brake pads.

- Maintain predictable braking response and pedal feel.

- Support safe road and performance driving conditions.

- Allow continued use of vehicles originally equipped with ceramic brakes.

These discs offer a practical braking solution where original ceramic components are no longer viable.

Why Do Ceramic Brake Discs Wear or Fail?

Although ceramic discs are highly durable, they are not immune to damage or wear.

Common Causes of Ceramic Disc Failure Include:

- Thermal

shock from improper bedding-in or rapid temperature changes.

- Impact

damage from road debris or incorrect handling.

- Surface

degradation from incorrect pad compounds.

- Cracking

or chipping due to extreme load cycles.

- High replacement cost, making repair impractical.

When ceramic discs fail, braking performance and safety can be compromised, requiring a suitable replacement solution.

Why Replace Ceramic Discs with Alternative Replacement Options?

Replacing worn or damaged ceramic discs with compatible replacement options provides a cost-effective and serviceable braking solution.

Key Benefits:

- Significantly lower replacement cost compared with ceramic discs.

- Reliable braking performance for road and fast-road use.

- Easier servicing and pad replacement.

- Consistent pedal feel and braking response.

- Practical solution for long-term ownership and maintenance.

Replacement discs allow drivers to retain confidence in their braking system without the expense of full ceramic disc replacement.

Highlights

- Replacement brake discs for vehicles originally fitted with ceramic systems.

- Cost-effective alternative to carbon-ceramic disc replacement.

- Predictable braking performance and pedal feel.

- Suitable for road and performance driving.

- Ideal for long-term maintenance and ownership.