Enter your VAT number here and click Verify:

Your details have been verified. VAT number registered to:

,

.

Your order will now be zero rated for VAT purposes. We reserve the right to verify these details after your order request has been made and reinstate VAT if required.

Your VAT details were not recognised or were invalid. Your VAT number must be matched to your Billing Country as specified above. This is currently specified as . You do not need to enter the country code part of your VAT number as this has already been selected in your billing address details above.

The VAT number checking service is currently offline. Please supply your VAT details within the comments or special instructions field below and we will apply a VAT discount after placing your order request.

EBC

Porsche EBC

In the early 80’s in Europe, EBC commenced developing the world’s first aftermarket range of products. After a successful launch in Europe, EBC expanded into the USA market in the mid-1980s. Expanding rapidly in the automotive industry, EBC Brakes has become a world leader in sport, high performance and race brake pads and disc/rotors with a massive trademark range of Porsche products. EBC produces 100% of its brake pad range in its own factories in the UK and USA and a huge proportion of its automotive brake discs are also UK and USA made

At Design911, EBC Brakes for Porsche models

At Design911, we stock a wide range of EBC Brakes products tailored for Porsche models, from everyday road pads and discs through to fast-road and performance-focused options. The EBC range covers popular compounds such as Green, Red and Yellow pads, alongside matching discs, allowing owners to choose combinations that suit commuting, touring or more spirited use.

EBC’s emphasis on in-house manufacturing, material development and application-specific friction compounds means Porsche drivers can select pads and discs that feel well matched to their driving style, whether the priority is low dust and refinement, a more responsive pedal, or dependable performance during enthusiastic road driving.

Sold as set of 4 pads for one axle.

#ebc

BMW M2 3.0 TURBO (F87) 2016-2018

BMW M2 COMPETITION 3.0 TWIN TURBO 2018-

BMW M3 3.0 TWIN TURBO (F80) 2014-

BMW M3 CS 3.0 TWIN TURBO (F80) 2017-

BMW M3 COMPETITION 3.0 TWIN TURBO (F80) 2016-

BMW M4 3.0 TWIN TURBO (F82) 2014-

BMW M4 CS 3.0 TWIN TURBO (F82) 2018-

BMW M4 COMPETITION 3.0 TWIN TURBO (F82) 2016-

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

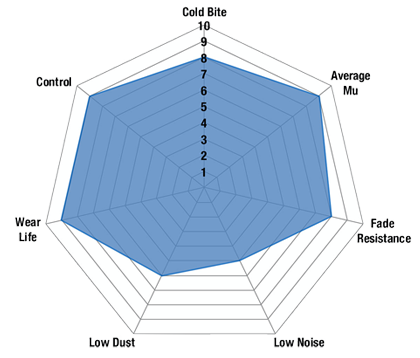

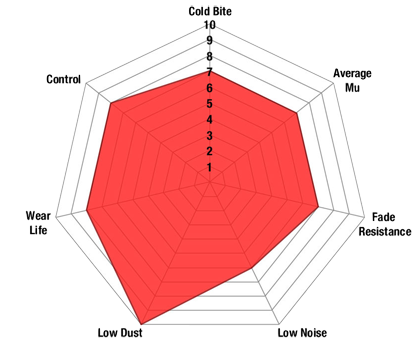

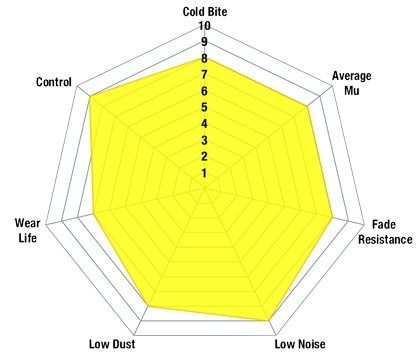

Performance

EBC Bluestuff are heat scorched which helps bedding times but you still need to take care especially on the highway and when using on part worn rotors. Use the brakes gently for 200 miles, gradually increasing demand on the brakes in a SAFE ROAD ENVIRONMENT until you feel totally confident and can evaluate their stopping distances in all traffic conditions.

Remember, it's down to you and your bedding-in process. If you do feel brake fade a couple of times and even smell the brakes, this is totally normal and once achieved and the brakes are allowed to cool, they will have improved a lot.

There are several ways of surface scorching pads and EBC has chosen an infra red lamp tunnel for surface preparation of its pad ranges. The furnace is now scorching all pads for resale including the Bluestuff NDX range.

Bedding Performance

The curve shows that friction builds quickly during bedding in even after 2-3 stops but in a real world TRACK USE where rotors may not be perfect and calipers not serviced weekly (like our lab dyno ones) the bedding in process with Blue may exhibit 20-25mm contact bands in the centre of the discs after 4-5 laps and on some standard street calipers some vibration.

This is simply the pad telling you " I cannot hold onto the disc at these torques until I am fully bedded in". If vibration happens you should continue driving whilst BRAKING EARLIER TO BE SAFE until the contact band widens to almost entire disc/rotor sweep at which point the vibration will stop. In street use the torques will not normally be enough to generate vibration during bed in but drive safely for 200 miles gentle brake use to bed in your new brakes and test them to performance in a safe and quiet road environment until you have total confidence that they are bedded. Hitting the brakes too hard, too soon can not only shorten pad life it may cause loss of brakes and an accident. Bed brakes in progressively.

Pre-bedding burns off a lot of the volatile organics in the brake pad surface by passing the pads under an apparatus similar to a toaster after manufacture for a few seconds; this chars the surface and the paint around the pad surface but the result is a major reduction in bed in time which all drivers will appreciate.

More information

Rotor condition. Is important, an off-flat or ribbed and grooved rotor will treble bed in times for street or track use, this is a harder and more durable pad and rotors should be in almost dead flat condition. If you need to have your rotors skimmed we recommend ONLY the very praiseworthy ON CAR brake lathes from Pro Cut.

Lifetime. ALWAYS inspect pads every 30 laps and discard when friction material is down to one eighth of an inch or 3mm to avoid fade. In street use the lifetime is considerable – 20,000 miles and upwards can be expected, even when driving hard.

Ducting and caliper drag. When using a street car brake system for racing, the mere insertion of a race formula pad does not transform your car into a track beast. Some cooling ducts often need to be added to give the brake system and pads a chance to survive race use.

Using Bluestuff NDX as a Street only pad. In Europe, the ECE R90 brake safety regulations require brake pads to have R90 certification when used on the road and with Bluestuff, this is not available for all cars. To find out if Bluestuff is R90 approved for your car, contact us.

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

FRONT

Two-piece floating slotted front iron disc upgrade with EBC Bluestuff brake pads

(including road centre-lock wheels).

This Product Fits:

Porsche 991 turbo 3.8ltr (Cast Iron Disc Only)

Porsche 991 turbo S 3.8 ltr (Cast Iron Disc Only)

Porsche 991.2 turbo 3.8ltr (Cast Iron Disc Only)

Porsche 991.2 turbo S 3.8 ltr (Cast Iron Disc Only)

Porsche 981 Cayman GT4 3.8ltr (Cast Iron Disc Only)

Disc size :

Front - 380 x 34 mm

EBC's fully floating 2-piece brake discs combined with our track focused Bluestuff pads represents the ultimate braking upgrade for high powered vehicles driven fast on road or frequently driven on track.

EBC's Bluestuff material is R90 approved and thus totally road legal yet has a higher emphasis placed on on-track performance, making it the perfect choice for customers who want to keep their car road-legal but demand excellent performance when they get to the racetrack.

Bluestuff has a high cold friction level, excellent pedal 'feel' and boasts a higher fade resistance over EBC's popular Yellowstuff compound.

EBC racings 2pc fully-floating brake discs are engineered from the finest materials without compromise, resulting in one of the highest quality 2-piece brake discs available on today's marketplace.

The outer friction rings are cast from high-carbon G3500 disc alloy, giving excellent wear properties and crack resistance even after heavy on-track use. EBC's patented stainless steel SD-Drive bobbins allow the braking ring to float freely and independently of the centre bell, reducing stresses and eliminating the chance of warping, whilst each bobbin location features an anti-rattle clip for totally silent operation.

All discs feature 48 curved vanes and are handed to each side of the car allowing effective heat dissipation. EBC 2-Piece discs often offer a weight saving over OEM parts, helping to reduce rotational un-sprung mass that has a positive effect on driving dynamics. Additionally, when the disc eventually becomes worn, the hub can be retained replacing only the outer friction ring which reduces long term operating costs

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

P2DK039B

The product you are viewing cross references to these numbers

- Porsche 991.1 Turbo 3.8L (520 Bhp) 2014-16

- Porsche 991.1 Turbo S 3.8L (560 Bhp) 2014-16

- Porsche 991.2 Turbo Coupe 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Coupe 3.8L (580 Bhp) 2016-19

- Porsche 991.2 Turbo Cabriolet 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Cabriolet 3.8L (580 Bhp) 2016-19

- Porsche Cayman GT4 3.8L 2015-16

Sold as set of 4 pads for one axle.

Porsche Macan 3.0 Twin Turbo 2015>> (Cast Iron Discs Only)

Porsche Macan 3.6 Twin Turbo 2014>> (Cast Iron Discs Only)

Porsche Macan 3.6 Twin Turbo (Performance Package) 2016>> (Cast Iron Discs Only)

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

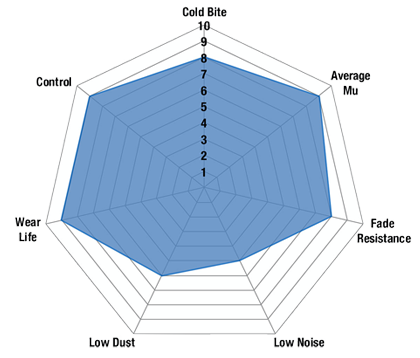

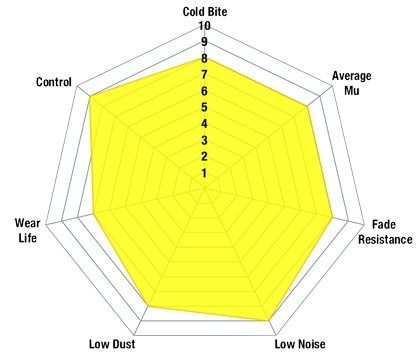

Performance

EBC Bluestuff are heat scorched which helps bedding times but you still need to take care especially on the highway and when using on part worn rotors. Use the brakes gently for 200 miles, gradually increasing demand on the brakes in a SAFE ROAD ENVIRONMENT until you feel totally confident and can evaluate their stopping distances in all traffic conditions.

Remember, it's down to you and your bedding-in process. If you do feel brake fade a couple of times and even smell the brakes, this is totally normal and once achieved and the brakes are allowed to cool, they will have improved a lot.

There are several ways of surface scorching pads and EBC has chosen an infra red lamp tunnel for surface preparation of its pad ranges. The furnace is now scorching all pads for resale including the Bluestuff NDX range.

Bedding Performance

The curve shows that friction builds quickly during bedding in even after 2-3 stops but in a real world TRACK USE where rotors may not be perfect and calipers not serviced weekly (like our lab dyno ones) the bedding in process with Blue may exhibit 20-25mm contact bands in the centre of the discs after 4-5 laps and on some standard street calipers some vibration.

This is simply the pad telling you " I cannot hold onto the disc at these torques until I am fully bedded in". If vibration happens you should continue driving whilst BRAKING EARLIER TO BE SAFE until the contact band widens to almost entire disc/rotor sweep at which point the vibration will stop. In street use the torques will not normally be enough to generate vibration during bed in but drive safely for 200 miles gentle brake use to bed in your new brakes and test them to performance in a safe and quiet road environment until you have total confidence that they are bedded. Hitting the brakes too hard, too soon can not only shorten pad life it may cause loss of brakes and an accident. Bed brakes in progressively.

Pre-bedding burns off a lot of the volatile organics in the brake pad surface by passing the pads under an apparatus similar to a toaster after manufacture for a few seconds; this chars the surface and the paint around the pad surface but the result is a major reduction in bed in time which all drivers will appreciate.

More information

Rotor condition. Is important, an off-flat or ribbed and grooved rotor will treble bed in times for street or track use, this is a harder and more durable pad and rotors should be in almost dead flat condition. If you need to have your rotors skimmed we recommend ONLY the very praiseworthy ON CAR brake lathes from Pro Cut.

Lifetime. ALWAYS inspect pads every 30 laps and discard when friction material is down to one eighth of an inch or 3mm to avoid fade. In street use the lifetime is considerable – 20,000 miles and upwards can be expected, even when driving hard.

Ducting and caliper drag. When using a street car brake system for racing, the mere insertion of a race formula pad does not transform your car into a track beast. Some cooling ducts often need to be added to give the brake system and pads a chance to survive race use.

Using Bluestuff NDX as a Street only pad. In Europe, the ECE R90 brake safety regulations require brake pads to have R90 certification when used on the road and with Bluestuff, this is not available for all cars. To find out if Bluestuff is R90 approved for your car, contact us.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52204NDX

The product you are viewing cross references to these numbers

- Porsche 95B.1 Macan S Petrol 3.0L V6 (340Bhp) 2014-18

- Porsche 95B.1 Macan Turbo 3.6L V6 (400Bhp) 2014-18

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 991 Carrera 3.4ltr - 2011 to 2015 (Cast Iron Disc Only)

Porsche 991 Carrera 4 3.4ltr - 2011 to 2015 (Cast Iron Disc Only)

Porsche 991.2 Carrera 3.0ltr - 2015 to2019 (Cast Iron Disc Only)

Porsche 991.2 Carrera 4 Targa 3.0ltr -2016 to 2019 Cast Iron Disc Only

Porsche 991.2 Carrera T 3.0ltr - 2018 to 2019 (Cast Iron Disc Only)

Porsche 981 Boxster Spyder 3.8ltr - 2015 to 2016 (Cast Iron Disc Only)

Porsche 718 Boxster GTS / Cayman GTS 4.0ltr (Cast Iron Disc Only

Porsche 958 Cayenne 3.0ltr Hybrid - 2010 to 2017

Porsche 958 Cayenne 3.6ltr - 2010 to 2017

Porsche 958 Cayenne GTS 3.6ltr Twin Turbo 440 2015-2017

Porsche 958 Cayenne S 4.8ltr - 2010 to 2017

Porsche 958 Cayenne GTS 4.8ltr - 2010 to 2015

Porsche 958 Cayenne turbo 4.8ltr - 2010 to 2017

Porsche 958 Cayenne turbo S 4.8ltr - 2012 to 2017

Porsche 958 Cayenne 3.0ltr Turbo Diesel - 2010 to 2017

Porsche 958 Cayenne 4.2ltr Twin Turbo Diesel - 2013 to 2017

Porsche 9YA Cayenne S 2.9ltr Twin Turbo 2017>>

Porsche 9YA Cayenne 4.0ltr Twin Turbo 2020>>

Porsche 9YA Cayenne Coupe S 2.9ltr Twin Turbo 2019>>

Porsche 9YA Cayenne Coupe 3.0ltr Turbo E-Hybrid 2019>>

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

A great all round sport and race pad, revised to a new improved formula in 2021 for faster bed-in.

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52098NDX

The product you are viewing cross references to these numbers

- Porsche Boxster 981 Spyder 3.8L 2016

- Porsche 991.1 Carrera C2 3.4L (350 Bhp) 2012-16

- Porsche 991.1 Carrera C4 3.4L (350 Bhp) 2012-16

- Porsche 991.2 Carrera 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Carrera 4 3.0L (370 Bhp) 2016-19

- Porsche Cayman GT4 718 4.0L / GT4 RS 718 4.0L

- Porsche 958 Cayenne V6 3.6L Petrol (300Hp) 2010-17

- Porsche 958 Cayenne V6 3.0L Diesel (245Hp) 2010-17

- Porsche 958 Cayenne S V6 3.0L Hybrid (380Hp) 2010-17

- Porsche 958 Cayenne S V8 4.8L Petrol (400Hp) 2010-17

- Porsche 958 Cayenne S V8 4.2L Diesel (382Hp) 2010-17

- Porsche 958 Cayenne GTS V8 4.8L Petrol (400Hp) 2010-17

- Porsche 958 Cayenne Turbo V8 4.8L Petrol (500Hp) 2010-17

- Porsche 958 Cayenne Turbo S V8 4.8L Petrol (550Hp) 2010-17

- Porsche 9YA Cayenne Coupe E-Hybrid V6 3.0L (340Hp) 2020-23

- Porsche 9YA Cayenne Coupe S V6 2.9L Petrol (440Hp) 2019-23

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 991 Carrera S 3.8ltr - 2011 to 2015 (Cast Iron Disc Only)

Porsche 991 Carrera 4S 3.8ltr - 2011 to 2015 (Cast Iron Disc Only)

Porsche 991 Carrera GTS 3.8ltr - 2014 to 2015 (Cast Iron Disc Only)

Porsche 991 Carrera 4 GTS 3.8ltr - 2014 to 2015 (Cast Iron Disc Only)

Porsche 991.2 Carrera 4S Targa 3.0ltr Twin Turbo - 2016 to 2019 (Cast Iron Disc Only)

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

A great all round sport and race pad, revised to a new improved formula in 2021 for faster bed-in.

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52144NDX

The product you are viewing cross references to these numbers

- Porsche 991.1 Carrera C2S / GTS 3.8L (400/430 Bhp) 2012-16

- Porsche 991.1 Carrera C4S / GTS 3.8L (400/430 Bhp) 2012-16

- Porsche 991.2 Targa 4S / GTS 3.0L (420/450 Bhp) 2016-19

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 997 Gen2 Carrera 3.6ltr – 2008 to 2012 (Cast Iron Disc Only)

Porsche 997 Gen2 Carrera 4 3.6ltr – 2008 to 2012 (Cast Iron Disc Only)

Porsche 991 Carrera 3.4ltr 2011-2015 (Cast Iron Disc Only)

Porsche 991 Carrera 4 3.4ltr - 2011 to 2015 (Cast Iron Disc Only)

Porsche 991 Carrera 3.4ltr – 2011 to 2015 (Cast Iron Disc Only)

Porsche 981 Boxster / Cayman 2.7ltr – 2012 to 2016 (Cast Iron Disc Only)

Porsche 981 Boxster S / Cayman S 3.4ltr – 2012 to 2016 (Cast Iron Disc Only)

Porsche 981 Boxster GTS / Cayman GTS 3.4ltr – 2014 to 2016 (Cast Iron Disc Only)

Porsche 981 Boxster Spyder 3.8ltr – 2015 to 2016 (Cast Iron Disc Only)

Porsche 718 Boxster / Cayman 2.0ltr turbo 2016>> (Cast Iron Disc Only)

Porsche 718 Boxster T / Cayman T 2.0ltr turbo 2016>> (Cast Iron Disc Only)

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

A great all round sport and race pad, revised to a new improved formula in 2021 for faster bed-in.

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52057NDX

The product you are viewing cross references to these numbers

- Porsche Boxster 981 2.7L 2012-16

- Porsche Boxster 981 S / GTS 3.4L 2012-16

- Porsche Boxster 981 Spyder 3.8L 2016

- Porsche Boxster 718 2.0L Manual (300 Bhp) 2017>>

- Porsche Boxster 718 2.0L PDK (300 Bhp) 2017>>

- Porsche Boxster T 718 2.0L Manual (300 Bhp) 01/2019>>

- Porsche Boxster T 718 2.0L PDK (300 Bhp) 01/2019>>

- Porsche 991.1 Carrera C2 3.4L (350 Bhp) 2012-16

- Porsche 991.1 Carrera C4 3.4L (350 Bhp) 2012-16

- Porsche Cayman 2.7L 981 2013-16

- Porsche Cayman S / GTS 3.4L 981 2013-16

- Porsche Cayman 718 2.0L Manual (300 Bhp)

- Porsche Cayman 718 2.0L PDK (300 Bhp)

- Porsche Cayman T 718 2.0L Manual (300 Bhp)

- Porsche Cayman T 718 2.0L PDK (300 Bhp)

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 991 GT3 3.8ltr - 2013 to 2015 (Cast Iron Disc Only)

Porsche 991 turbo / turbo S 3.8ltr - 2013 to 2015 (Cast Iron Disc Only)

Porsche 991.2 Carrera S / Carrera 4S 3.0lt - 2015 to 2019 (Cast Iron Disc Only)

Porsche 991.2 Carrera GTS 3.0ltr 2017-2019 (Cast Iron Disc Only)

Porsche 991.2 turbo / turbo S 3.8ltr 2015-2019 (Cast Iron Disc Only)

Porsche 991.2 GT3 3.8ltr 2015-2019 (Cast Iron Disc Only)

Porsche 991.2 GT3 RS 4.0ltr 2015-2018 (Cast Iron Disc Only)

Porsche 992 Carrera S 3.0ltr 2019>> (Cast Iron Disc Only)

Porsche 992 Carrera 4S 3.0ltr 2019>> (Cast Iron Disc Only)

Porsche 981 Cayman GT4 3.8ltr 2015-2016 (Cast Iron Disc Only)

Porsche 718 Boxster GTS 4.0ltr 2020>> (Cast Iron Disc Only)

Porsche 718 Cayman GTS 4.0ltr 2020>> (Cast Iron Disc Only)

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

A great all round sport and race pad, revised to a new improved formula in 2021 for faster bed-in.

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52206NDX

The product you are viewing cross references to these numbers

- Porsche Boxster GTS 718 4.0L Manual (400 Bhp) 01/2019>>

- Porsche Boxster GTS 718 4.0L PDK (400 Bhp) 01/2019>>

- Porsche 991.1 Turbo 3.8L (520 Bhp) 2014-16

- Porsche 991.1 Turbo S 3.8L (560 Bhp) 2014-16

- Porsche 991.1 GT3 3.8L (475 Bhp) 2014-16

- Porsche 991.2 Carrera 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Carrera 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Targa 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Turbo Coupe 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Coupe 3.8L (580 Bhp) 2016-19

- Porsche 991.2 Turbo Cabriolet 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Cabriolet 3.8L (580 Bhp) 2016-19

- Porsche 991.2 GT3 4.0L (500 Bhp) / GT3 RS 4.0L (520 Bhp) 2017-19

- Porsche 992.1 Carrera 2S / GTS 3.0L 2019-24

- Porsche 992.1 Carrera 4S / GTS 3.0L 2019-24

- Porsche 992.1 Carrera 2S / GTS Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4S / GTS Cabriolet 3.0L 2019-24

- Porsche 992.1 Targa 4S / GTS 3.0L 2020-24

- Porsche Cayman GT4 3.8L 2015-16

- Porsche Cayman GTS 718 4.0L Manual (400 Bhp)

- Porsche Cayman GTS 718 4.0L PDK (400 Bhp)

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 991.1 3.8 GT3 - 2013 to 2015 (Cast Iron Disc Only)

Porsche 991.1 turbo / turbo S 3.8ltr - 2013 to 2015 (Cast Iron Disc Only)

Porsche 991.2 GT3 3.8ltr - 2015>> (Cast Iron Disc Only)

Porsche 991.2 GT3 RS 4.0ltr - 2015>> (Cast Iron Disc Only)

Porsche 991.2 turbo / turbo S 3.8ltr - 2015>> (Cast Iron Disc Only)

Porsche 981 Cayman GT4 3.8ltr - 2015-2016 (Cast Iron Discs only)

Porsche 718 Cayman GT4 4.0ltr 2019>> (Cast Iron Discs only)

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

A great all round sport and race pad, revised to a new improved formula in 2021 for faster bed-in.

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52207NDX

The product you are viewing cross references to these numbers

- Porsche 991.1 Turbo 3.8L (520 Bhp) 2014-16

- Porsche 991.1 Turbo S 3.8L (560 Bhp) 2014-16

- Porsche 991.1 GT3 3.8L (475 Bhp) 2014-16

- Porsche 991.2 Turbo Coupe 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Coupe 3.8L (580 Bhp) 2016-19

- Porsche 991.2 Turbo Cabriolet 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Cabriolet 3.8L (580 Bhp) 2016-19

- Porsche 991.2 GT3 4.0L (500 Bhp) / GT3 RS 4.0L (520 Bhp) 2017-19

- Porsche 991.2 GT2 RS 3.8L PDK (700 bhp) 2018-19

- Porsche Cayman GT4 3.8L 2015-16

- Porsche Cayman GT4 718 4.0L / GT4 RS 718 4.0L

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

cast iron discs only

- Porsche Boxster Spyder 718 4.0L (420 Bhp)

- Porsche 991.1 Turbo 3.8L (520bhp) 2014-16

- Porsche 991.1 Turbo S 3.8L (560Bhp) 2014-16

- Porsche 991.1 GT3 3.8L (475Bhp) 2014-16

- Porsche 991.2 Turbo Coupe 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Coupe 3.8L (580 Bhp) 2016-19

- Porsche 991.2 Turbo Cabriolet 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Cabriolet 3.8L (580 Bhp) 2016-19

- Porsche 991.2 GT3 4.0L (500 Bhp) / GT3 RS 4.0L (520 Bhp) 2017-19

- Porsche 992.1 GT3 4.0L / 992 S/T 4.0L 2021-24

- Porsche Cayman GT4 3.8L 2015-16

- Porsche Cayman GT4 718 4.0L

Yellowstuff ⁃ A first in a new range of 'Hybrid' materials that can be safely and legally used on worlds roads being R90 approved UK are a high friction upgrade pad for all fast street use and can also be used on the track with proper bedding (see bed in procedures)

Yellowstuff has been the flagship pad by EBC for over a decade and gives instant brake response, great feel and modulations with silk-smooth noise free braking and was also improved in 2021 to be copper free and conform to all new legislations for the environment and our pads are fully shimmed chamfered and slotted .

Yellow arrives with pad surface Brake-in coating to accelerate pad bedding after install.

• 0.48 stable friction once bedded

• Strong initial bite ,work from cold

• Zero rotor damage

• Short to medium race lifetime

• Copper free for ECO compliance

If planning track use we recommend using the pad for a period on the street to pre bed before making a track excursion. If you require faster track bedding also consider our new Bluestuff R 90 approved compound which beds in faster.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP42207R

The product you are viewing cross references to these numbers

- Porsche Boxster Spyder / Sypder RS 718 4.0L 01/2019>>

- Porsche 991.1 Turbo 3.8L (520 Bhp) 2014-16

- Porsche 991.1 Turbo S 3.8L (560 Bhp) 2014-16

- Porsche 991.1 GT3 3.8L (475 Bhp) 2014-16

- Porsche 991.2 Turbo Coupe 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Coupe 3.8L (580 Bhp) 2016-19

- Porsche 991.2 Turbo Cabriolet 3.8L (540 Bhp) 2016-19

- Porsche 991.2 Turbo S Cabriolet 3.8L (580 Bhp) 2016-19

- Porsche 991.2 GT3 4.0L (500 Bhp) / GT3 RS 4.0L (520 Bhp) 2017-19

- Porsche 992.1 GT3 4.0L / 992 S/T 4.0L 2021-24

- Porsche Cayman GT4 3.8L 2015-16

- Porsche Cayman GT4 718 4.0L / GT4 RS 718 4.0L

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 991.2 3.0 Twin Turbo C2 / C4 / C4 Targa 2015>> (Cast Iron Disc Only) (Front)

Porsche 991.2 3.0 Twin Turbo Carrera GTS / 4 GTS / 4 GTS Targa 2017>> (Cast Iron Disc Only) (Front)

Porsche 992 Carrera / Carrera 4 3.0 2019>> (Cast Iron Disc Only) (Front)

Porsche 982 Boxster (718) S / GTS 2.5 Turbo 2016>> (Cast Iron Disc Only) (Front)

Porsche 982 Cayman (718) S / GTS 2.5 Turbo 2016>> (Cast Iron Disc Only) (Front)

EBC Bluestuff NDX

Super-Street & Trackday Brake Pads

Bluestuff NDX is a high friction sport and race material that now has R90 approval on almost all fitments for the EU. For USA and Asia markets where R90 does not apply, this compound is totally road safe and the perfect choice for performance vehicles driven hard on the road or track days.

Product Information

When we say "Trackday" don't underestimate this fantastic material.

The reason we draw users' attention to the words Trackday ( also known in the USA as lapping ) is because of this material's fantastic ability to bed in quickly. Weekend fit and go drivers do not want to spend their laps bedding in brake pads.

Yet when used on more serious race track drivers this material delights and up to rotor temps of 550C /1030 F Bluestuff is the way to go. This material has been used by numerous spec series cup car racing groups in Europe.

The NDX pad material is bonded to the steel backing plates using the patented NUCAP NRS hook system which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high-volume Vee grooves to catch the larger amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with a much enhanced lifetime over our previous Yellowstuff grade pads.

R&D Manager Steve Payne checks out the first batch of the Bluestuff NDX material made with a revolutionary process to produce the highly acclaimed EBC Bluestuff NDX Race Pads. The process involves 5 steps never before used in friction materials and sets EBC Brakes firmly in the lead as a provider of brake friction.

Bluestuff is available in NDX high friction version at 0.52 Mu and a lower B version for many rear applications on lighter cars with a lower 0.42 Mu.

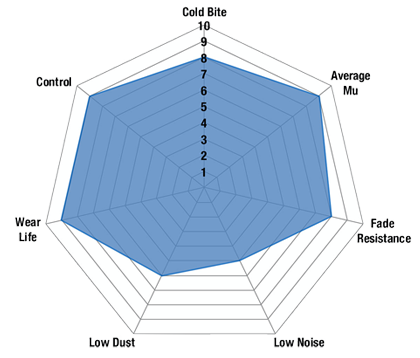

Performance

EBC Bluestuff are heat scorched which helps bedding times but you still need to take care especially on the highway and when using on part worn rotors. Use the brakes gently for 200 miles, gradually increasing demand on the brakes in a SAFE ROAD ENVIRONMENT until you feel totally confident and can evaluate their stopping distances in all traffic conditions.

Remember, it's down to you and your bedding-in process. If you do feel brake fade a couple of times and even smell the brakes, this is totally normal and once achieved and the brakes are allowed to cool, they will have improved a lot.

There are several ways of surface scorching pads and EBC has chosen an infra red lamp tunnel for surface preparation of its pad ranges. The furnace is now scorching all pads for resale including the Bluestuff NDX range.

Bedding Performance

The curve shows that friction builds quickly during bedding in even after 2-3 stops but in a real world TRACK USE where rotors may not be perfect and calipers not serviced weekly (like our lab dyno ones) the bedding in process with Blue may exhibit 20-25mm contact bands in the centre of the discs after 4-5 laps and on some standard street calipers some vibration.

This is simply the pad telling you " I cannot hold onto the disc at these torques until I am fully bedded in". If vibration happens you should continue driving whilst BRAKING EARLIER TO BE SAFE until the contact band widens to almost entire disc/rotor sweep at which point the vibration will stop. In street use the torques will not normally be enough to generate vibration during bed in but drive safely for 200 miles gentle brake use to bed in your new brakes and test them to performance in a safe and quiet road environment until you have total confidence that they are bedded. Hitting the brakes too hard, too soon can not only shorten pad life it may cause loss of brakes and an accident. Bed brakes in progressively.

Pre-bedding burns off a lot of the volatile organics in the brake pad surface by passing the pads under an apparatus similar to a toaster after manufacture for a few seconds; this chars the surface and the paint around the pad surface but the result is a major reduction in bed in time which all drivers will appreciate.

More information

Rotor condition. Is important, an off-flat or ribbed and grooved rotor will treble bed in times for street or track use, this is a harder and more durable pad and rotors should be in almost dead flat condition. If you need to have your rotors skimmed we recommend ONLY the very praiseworthy ON CAR brake lathes from Pro Cut.

Lifetime. ALWAYS inspect pads every 30 laps and discard when friction material is down to one eighth of an inch or 3mm to avoid fade. In street use the lifetime is considerable – 20,000 miles and upwards can be expected, even when driving hard.

Ducting and caliper drag. When using a street car brake system for racing, the mere insertion of a race formula pad does not transform your car into a track beast. Some cooling ducts often need to be added to give the brake system and pads a chance to survive race use.

Using Bluestuff NDX as a Street only pad. In Europe, the ECE R90 brake safety regulations require brake pads to have R90 certification when used on the road and with Bluestuff, this is not available for all cars. To find out if Bluestuff is R90 approved for your car, contact us.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP52307NDX

The product you are viewing cross references to these numbers

- Porsche Boxster S 718 2.5L Manual (350 Bhp) 05/2017>>

- Porsche Boxster S 718 2.5L PDK (350 Bhp) 05/2017>>

- Porsche Boxster GTS 718 2.5L Manual (365 Bhp) 05/2017>>

- Porsche Boxster GTS 718 2.5L PDK (365 Bhp) 05/2017>>

- Porsche 991.2 Carrera 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Carrera 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Targa 4 3.0L (370 Bhp) 2016-19

- Porsche 992.1 Carrera 2 3.0L 2019-24

- Porsche 992.1 Carrera 4 3.0L 2019-24

- Porsche 992.1 Carrera 2 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4 Cabriolet 3.0L 2019-24

- Porsche Cayman S 718 2.5L Manual (350 Bhp)

- Porsche Cayman S 718 2.5L PDK (350 Bhp)

- Porsche Cayman GTS 718 2.5L Manual (365 Bhp)

- Porsche Cayman GTS 718 2.5L PDK (365 Bhp)

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

Porsche 991 S 3.8L

Porsche 991.2 3.0L

Porsche 991.2 S 3.0L

EBC Redstuff Ceramic Brake Pads

As EBC's flagship street brake pad material for prestige and faster cars, EBC Redstuff ceramic Brake pads sets new standards in brake performance.

Product Information

High friction formula improves brake effect 15%.

Redstuff ceramic brake pads have always been known for its low dust ability but the latest blend has greatly reduced the phenomenon of pad "Pick up" or disc scoring and reduced dust even further. Tested at the UK Motor Industries Research Association (MIRA) in witnessed tests early Redstuff reduced car stopping distance in tests by almost 50 feet from 100 MPH offering a staggering 30% brake improvement.

✔ Redstuff ceramic brake pads, passenger car/saloon car pad NOT made for Truck or SUV fitments

✔ EBC lowest dust fast street pad with 15% brake improvement

✔ Capable of repeated heavy brake use without brake "Fall-Off"

✔ Very minimal disc/rotor damage characteristics

✔ Superb material for Prestige imports/European and Asian cars

✔ ECE R 90 type approved for most cars

Features red "brake in' surface coating for instant safe braking after install

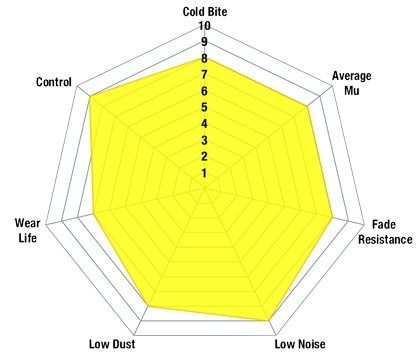

Performance

High Performance lowest dust rating pads for Prestige imports and faster street driving.

There are two reasons our customers love Redstuff, First because they are the lowest dust pad we have encountered by reducing dust by 60-90%. Plus the minimal dust you see is very easily removed with a simple sponge wash as it contains no steel fibre particles as in all other pads. Second they brake like an alligator right from cold (as good as Original pads or better) and just get better as they heat up.

This material is a aramid fibre based brake compound enhanced with ceramic particles. If you have previously tried EBC redstuff (pre-ceramic compound) this material is light years ahead. It lasts longer, it brakes better and is quieter.

Technical Info:

Being a hard wearing pad, bed-in times can be as long as 1000 miles and drivers must be patient until the pad takes up the shape of their disc (brake rotor). This is a truly impressive fast road pad for repeated heavy braking.

It emits far less dust than semi-metallic pads and has been proven to stop a passenger car/sedan/sport compact/hot hatch 13 metres quicker than OEM pads from 100mph/160kph. Features EBC Brake-In surface coating which conditions rotor surface and accelerates pad bed-in. Nominal friction coefficient 0.5 with approx. 50% dust reduction. Most EBC Red Ceramic pads are approved to ECE R90 brake safety regulation.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP32371C

The product you are viewing cross references to these numbers

- Porsche 991.1 Carrera C2S / GTS 3.8L (400/430 Bhp) 2012-16

- Porsche 991.1 Carrera C4S / GTS 3.8L (400/430 Bhp) 2012-16

- Porsche 991.2 Carrera 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Carrera 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Carrera 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Carrera 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Targa 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Targa 4S / GTS 3.0L (420/450 Bhp) 2016-19

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

- Porsche 991.2 Carrera 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Carrera 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Targa 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 992.1 Carrera 2 3.0L 2019-24

- Porsche 992.1 Carrera 4 3.0L 2019-24

- Porsche 992.1 Carrera 2 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 2S / GTS 3.0L 2019-24

- Porsche 992.1 Carrera 4S / GTS 3.0L 2019-24

- Porsche 992.1 Carrera 2S / GTS Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4S / GTS Cabriolet 3.0L 2019-24

- Porsche 992.1 Targa 4 3.0L 2020-24

- Porsche 992.1 Targa 4S / GTS 3.0L 2020-24

- Porsche 992.2 Carrera 2 3.0L 2024>>

- Porsche 992.2 Carrera 2 3.0L Cabriolet 2024>>

- Porsche 9YA Cayenne Turbo V8 4.0L Petrol 550Hp 2020-23

- Porsche 9YA Cayenne Coupe Turbo V8 4.0L Petrol 550Hp 2019-23

EBC Yellowstuff 3068 compound is new for 2021, it has high friction from cold, not requiring warm-up for street use yet when loaded up and really hot the brakes just get better.

High-efficiency performance pad for high friction and improved stopping power.

Not only a high friction pad but very resistant to heat and lots of heavy braking means that Yellowstuff has been used with great success in fast street cars and Police vehicle brakes alike.

EBC Yellowstuff was upgraded during 2021 to remove copper from the mix to comply with environmental legislations and as the new mix lasts longer it is not now being suggested as a track material due to the longer bedding in process required. On the street, bedding happens naturally in the first 100-200 miles of urban use but for those drivers wishing to arrive at the track with new pads and enjoy their day, our current suggestion is to use the Bluestuff formulation for track day driving both front and rear.

Because of its huge heat range, the applications where EBC Yellowstuff will deliver benefits range from fastest street use on higher horsepower cars on most street-based cars and even as a brake upgrade on Trucks and SUV.

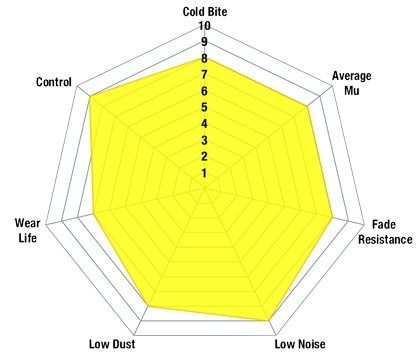

PERFORMANCE

High friction formula improves brake effect by 15%

Fastest street use material, R90 street-legal high-performance pad

✔ Silky smooth and quiet braking on all applications

✔ Capable of repeated heavy brake use without brake "Fall-Off"

✔ Very minimal disc/rotor damage characteristics

✔ Medium hardness material feels good at pedal

✔ If all you need is stopping power, this is the material choice

✔ ECE R 90 type approved for most cars

✔ Features red "brake in' surface coating for instant safe braking after install

In trackday/drift/hillclimb races where earlier Yellow blends were suggested – EBC Bluestuff NDX or the RPX ranges are now the better choices

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP42371R

The product you are viewing cross references to these numbers

- Porsche 991.2 Carrera 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Carrera 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 991.2 Targa 4S / GTS 3.0L (420/450 Bhp) 2016-19

- Porsche 992.1 Carrera 2 3.0L 2019-24

- Porsche 992.1 Carrera 4 3.0L 2019-24

- Porsche 992.1 Carrera 2 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 2S / GTS 3.0L 2019-24

- Porsche 992.1 Carrera 4S / GTS 3.0L 2019-24

- Porsche 992.1 Carrera 2S / GTS Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4S / GTS Cabriolet 3.0L 2019-24

- Porsche 992.1 Targa 4 3.0L 2020-24

- Porsche 992.1 Targa 4S / GTS 3.0L 2020-24

- Porsche 992.2 Carrera 2 3.0L 2024>>

- Porsche 992.2 Carrera 2 3.0L Cabriolet 2024>>

- Porsche 9YA Cayenne Turbo V8 4.0L Petrol (550Hp) 2020-23

- Porsche 9YA Cayenne Coupe Turbo V8 4.0L Petrol (550Hp) 2019-23

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

PORSCHE Macan 3.0ltr Diesel 2014>> (Cast Iron Discs Only) (front)

PORSCHE Macan S 3.0ltr 2014>> (Cast Iron Discs Only) (front)

PORSCHE 971 Panamera (2nd Gen) 2.9 Twin Turbo E-Hybrid 2016>> (Cast Iron Discs only)

PORSCHE 971 Panamera (2nd Gen) 3.0 Turbo 2016>> (Cast Iron Discs only)

EBC Yellowstuff 3068 compound is new for 2021, it has high friction from cold, not requiring warm-up for street use yet when loaded up and really hot the brakes just get better.

High-efficiency performance pad for high friction and improved stopping power.

Not only a high friction pad but very resistant to heat and lots of heavy braking means that Yellowstuff has been used with great success in fast street cars and Police vehicle brakes alike.

EBC Yellowstuff was upgraded during 2021 to remove copper from the mix to comply with environmental legislations and as the new mix lasts longer it is not now being suggested as a track material due to the longer bedding in process required. On the street, bedding happens naturally in the first 100-200 miles of urban use but for those drivers wishing to arrive at the track with new pads and enjoy their day, our current suggestion is to use the Bluestuff formulation for track day driving both front and rear.

Because of its huge heat range, the applications where EBC Yellowstuff will deliver benefits range from fastest street use on higher horsepower cars on most street-based cars and even as a brake upgrade on Trucks and SUV.

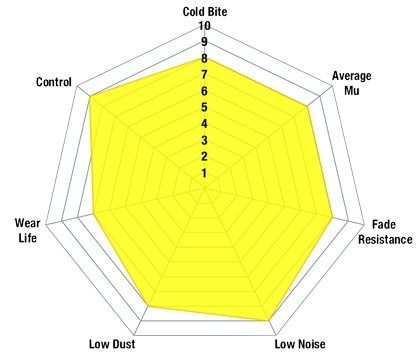

PERFORMANCE

High friction formula improves brake effect by 15%

Fastest street use material, R90 street-legal high-performance pad

✔ Silky smooth and quiet braking on all applications

✔ Capable of repeated heavy brake use without brake "Fall-Off"

✔ Very minimal disc/rotor damage characteristics

✔ Medium hardness material feels good at pedal

✔ If all you need is stopping power, this is the material choice

✔ ECE R 90 type approved for most cars

✔ Features red "brake in' surface coating for instant safe braking after install

In trackday/drift/hillclimb races where earlier Yellow blends were suggested – EBC Bluestuff NDX or the RPX ranges are now the better choices

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP42203R

The product you are viewing cross references to these numbers

- Porsche 971.1 Panamera V6 3.0L 2WD (330 Hp) 2017-20

- Porsche 971.1 Panamera 4 V6 3.0L 4WD (330 Hp) 2017-20

- Porsche 971.1 Panamera 4 V6 3.0L 4WD Executive 2017-20

- Porsche 971.1 Panamera 4S V6 3.0L 4WD (440 Hp) 2017-20

- Porsche 971.1 Panamera 4S V6 3.0L 4WD Executive 2017-20

- Porsche 971.1 Panamera 4 E-Hybrid V6 2.9L 4WD 2017-20

- Porsche 95B.1 Macan S Petrol 3.0L V6 (340Bhp) 2014-18

- Porsche 95B.1 Macan S Diesel 3.0L V6 (258Bhp) 2014-18

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

- Porsche 95B.1 Macan Petrol 2.0L 237Bhp 2014-18

- Porsche 95B.2 Macan Petrol 2.0L 245Bhp 2019-21

EBC Yellowstuff 3068 compound is new for 2021, it has high friction from cold, not requiring warm-up for street use yet when loaded up and really hot the brakes just get better.

High-efficiency performance pad for high friction and improved stopping power.

Not only a high friction pad but very resistant to heat and lots of heavy braking means that Yellowstuff has been used with great success in fast street cars and Police vehicle brakes alike.

EBC Yellowstuff was upgraded during 2021 to remove copper from the mix to comply with environmental legislations and as the new mix lasts longer it is not now being suggested as a track material due to the longer bedding in process required. On the street, bedding happens naturally in the first 100-200 miles of urban use but for those drivers wishing to arrive at the track with new pads and enjoy their day, our current suggestion is to use the Bluestuff formulation for track day driving both front and rear.

Because of its huge heat range, the applications where EBC Yellowstuff will deliver benefits range from fastest street use on higher horsepower cars on most street-based cars and even as a brake upgrade on Trucks and SUV.

PERFORMANCE

High friction formula improves brake effect by 15%

Fastest street use material, R90 street-legal high-performance pad

✔ Silky smooth and quiet braking on all applications

✔ Capable of repeated heavy brake use without brake "Fall-Off"

✔ Very minimal disc/rotor damage characteristics

✔ Medium hardness material feels good at pedal

✔ If all you need is stopping power, this is the material choice

✔ ECE R 90 type approved for most cars

✔ Features red "brake in' surface coating for instant safe braking after install

In trackday/drift/hillclimb races where earlier Yellow blends were suggested – EBC Bluestuff NDX or the RPX ranges are now the better choices

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP42168R

The product you are viewing cross references to these numbers

- Porsche 95B.1 Macan Petrol 2.0L (237Bhp) 2014-18

- Porsche 95B.2 Macan Petrol 2.0L (245Bhp) 2019-21

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

PORSCHE 958 Cayenne (92A) 3.6 2010-2017 (Front)

PORSCHE 958 Cayenne (92A) 3.0 TD 2010-2017 (Front)

EBC Yellowstuff 3068 compound is new for 2021, it has high friction from cold, not requiring warm-up for street use yet when loaded up and really hot the brakes just get better.

High-efficiency performance pad for high friction and improved stopping power.

Not only a high friction pad but very resistant to heat and lots of heavy braking means that Yellowstuff has been used with great success in fast street cars and Police vehicle brakes alike.

EBC Yellowstuff was upgraded during 2021 to remove copper from the mix to comply with environmental legislations and as the new mix lasts longer it is not now being suggested as a track material due to the longer bedding in process required. On the street, bedding happens naturally in the first 100-200 miles of urban use but for those drivers wishing to arrive at the track with new pads and enjoy their day, our current suggestion is to use the Bluestuff formulation for track day driving both front and rear.

Because of its huge heat range, the applications where EBC Yellowstuff will deliver benefits range from fastest street use on higher horsepower cars on most street-based cars and even as a brake upgrade on Trucks and SUV.

PERFORMANCE

High friction formula improves brake effect by 15%

Fastest street use material, R90 street-legal high-performance pad

✔ Silky smooth and quiet braking on all applications

✔ Capable of repeated heavy brake use without brake "Fall-Off"

✔ Very minimal disc/rotor damage characteristics

✔ Medium hardness material feels good at pedal

✔ If all you need is stopping power, this is the material choice

✔ ECE R 90 type approved for most cars

✔ Features red "brake in' surface coating for instant safe braking after install

In trackday/drift/hillclimb races where earlier Yellow blends were suggested – EBC Bluestuff NDX or the RPX ranges are now the better choices

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP42162R

The product you are viewing cross references to these numbers

- Porsche 958 Cayenne V6 3.6L Petrol (300Hp) 2010-17

- Porsche 958 Cayenne V6 3.0L Diesel (245Hp) 2010-17

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery

Sold as set of 4 pads for one axle.

for cast iron discs only

- Porsche Boxster S 718 2.5L Manual (350 Bhp)

- Porsche Boxster S 718 2.5L PDK (350 Bhp)

- Porsche Boxster GTS 718 2.5L Manual (365 Bhp)

- Porsche Boxster GTS 718 2.5L PDK (365 Bhp)

- Porsche 991.2 Carrera 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Carrera 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Targa 4 3.0L (370 Bhp) 2016-19

- Porsche 992.1 Carrera 2 3.0L 2019-24

- Porsche 992.1 Carrera 4 3.0L 2019-24

- Porsche 992.1 Carrera 2 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4 Cabriolet 3.0L 2019-24

- Porsche Cayman S 718 2.5L Manual (350Bhp)

- Porsche Cayman S 718 2.5L PDK (350Bhp)

- Porsche Cayman GTS 718 2.5L Manual (365 Bhp)

- Porsche Cayman GTS 718 2.5L PDK (365 Bhp)

High-efficiency performance pad for high friction and improved stopping power.

Not only a high friction pad but very resistant to heat and lots of heavy braking means that Yellowstuff has been used with great success in fast street cars and Police vehicle brakes alike.

EBC Yellowstuff was upgraded during 2021 to remove copper from the mix to comply with environmental legislations and as the new mix lasts longer it is not now being suggested as a track material due to the longer bedding in process required. On the street, bedding happens naturally in the first 100-200 miles of urban use but for those drivers wishing to arrive at the track with new pads and enjoy their day, our current suggestion is to use the Bluestuff formulation for track day driving both front and rear.

Because of its huge heat range, the applications where EBC Yellowstuff will deliver benefits range from fastest street use on higher horsepower cars on most street-based cars and even as a brake upgrade on Trucks and SUV.

PERFORMANCE

High friction formula improves brake effect by 15%

Fastest street use material, R90 street-legal high-performance pad

✔ Silky smooth and quiet braking on all applications

✔ Capable of repeated heavy brake use without brake "Fall-Off"

✔ Very minimal disc/rotor damage characteristics

✔ Medium hardness material feels good at pedal

✔ If all you need is stopping power, this is the material choice

✔ ECE R 90 type approved for most cars

✔ Features red "brake in' surface coating for instant safe braking after install

In trackday/drift/hillclimb races where earlier Yellow blends were suggested – EBC Bluestuff NDX or the RPX ranges are now the better choices

NOTE: Please ring for more details

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

DP42307R

The product you are viewing cross references to these numbers

- Porsche Boxster S 718 2.5L Manual (350 Bhp) 05/2017>>

- Porsche Boxster S 718 2.5L PDK (350 Bhp) 05/2017>>

- Porsche Boxster GTS 718 2.5L Manual (365 Bhp) 05/2017>>

- Porsche Boxster GTS 718 2.5L PDK (365 Bhp) 05/2017>>

- Porsche 991.2 Carrera 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Carrera 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 2 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Cabriolet 4 3.0L (370 Bhp) 2016-19

- Porsche 991.2 Targa 4 3.0L (370 Bhp) 2016-19

- Porsche 992.1 Carrera 2 3.0L 2019-24

- Porsche 992.1 Carrera 4 3.0L 2019-24

- Porsche 992.1 Carrera 2 Cabriolet 3.0L 2019-24

- Porsche 992.1 Carrera 4 Cabriolet 3.0L 2019-24

- Porsche Cayman S 718 2.5L Manual (350 Bhp)

- Porsche Cayman S 718 2.5L PDK (350 Bhp)

- Porsche Cayman GTS 718 2.5L Manual (365 Bhp)

- Porsche Cayman GTS 718 2.5L PDK (365 Bhp)

Shop Securely

Shop Securely

12 Month Warranty

12 Month Warranty

Worldwide Delivery

Worldwide Delivery